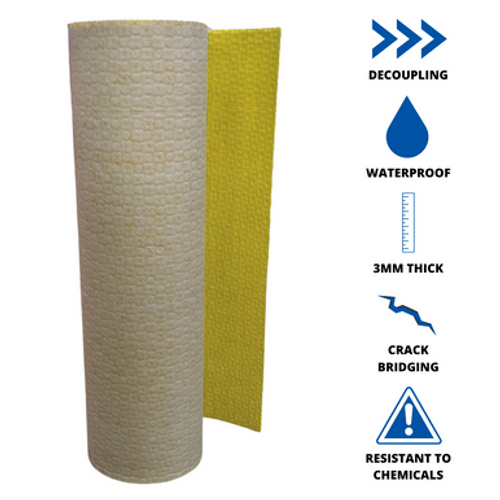

Dural Durabase Matting is a multi functional decoupling matting system. It's designed to be laid on wooden floors and newly laid concrete floors to prevent any cracks in the foundation from affecting the tiles. It does this by isolating the new tiled flooring from the substrate below. Dural Durabase Matting is 3mm thick and is suitable to use with most underfloor heating systems.

Durabase matting is easy to use on concrete and timber floors, chipboard, floorboards, MDF, metal surfaces, and asphalt. Dural Durabase CI matting has a 3 layer construction and are made from yellow polythene with a grid of texturing nodules and a supporting polypropylene fleece layer on the back. The combination ensures that the matting is resistant to most chemicals including salts, acids, alkalis, solvents, and oils. Air channels are created to equalise water vapour pressure and spread heat evenly when used with an underfloor heating system.

Quick and easy to install, Dural Durabase Matting measures 1 metre wide for easy measurement and accurate coverage. It is the ideal solution for fixing new and old problematic flooring, including those with a lot of lateral movement or cracking. Protect your tiles and your floor with Dural Durabase CI Decoupling Matting - sold by the square metre at The London Tile Co!

Features & Benefits of Dural Durabase CI Matting

How to install Dural Durabase matting

1. When cutting the matting to size, make sure that of the CI++ decoupling matting and the associated ceramic tiled surfaces are not force fitted due to the thermal-related stresses and footfall sound protection. Depending on the flooring construction and the specific site conditions, edge joints with a width of approx. 5–10 mm (or larger as required) must be produced.

2. Use a notched or serrated trowel like the Ardex B1 2mm trowel to apply Ardex AF200 or a thin-bed mortar to the subsurface. N.B.: Never use a notched or serrated trowel larger than 4 x 4mm, otherwise the decoupling effect of the CI++ matting will be impaired. The adhesive should be selected according to the subsurface type. The adhesive must bond and mechanically join to the carrier fabric of the DURABASE CI++- matting. With most subsurfaces, it is possible to use a hydraulic-setting flexible mortar, or a quick-bonding flexible adhesive in accordance with DIN EN 12004 / C2.

3. It is essential that the entire surface of the backing fabric of the cut-to-size mats is embedded into the adhesive. Loose laying of the CI++ mats is not possible. Work in the matting using a pressure roller or other suitable tool. Here, pay attention to the adhesive bonding time. For use as a compound seal, additionally apply DURABASE WP sealing tape to the mat joints to waterproof. For inward and outward facing corners, use the prefabricated moulded parts. Work in expansion joints using loops of WP sealing tape to produce a waterproof seal.

4. For indoor applications, tiles can be laid immediately after adhesion of the DURABASE CI++ matting using the thin-bed procedure and thin-bed mortar which fulfils the requirements of the surface covering. Here it is advisable to smooth out any mat depressions and then apply the thin-bed mortar using the trowel in a single work step. The notching size of the trowel must correspond to the tile format for tile laying. The tiles must be embedded across their entire surface into the adhesive. The indicated available laying time of the thin-bed mortar must be taken into account. In terms of working procedure, it is also possible to wait for the filler to harden before laying the tiles. For outdoor flooring surfaces, highly frequented areas and large-format tiles, tile laying may not commence until the CI++ filler has hardened. Tiles in thin material thicknesses (slim tiles and slim / 4-tiles) are not suitable (risk of breakage). Furthermore, small format tiles measuring less than 50 x 50 mm may not be used. To prevent damage to the installed matting, protection from extreme mechanical stresses should be provided by the use of running boards.

Notes: During the installation of DURABASE CI++ matting on balconies and terraces under high summer temperatures, the matting should be protected using suitable measures in order to prevent any possible loosening or detachment of the mats and the formation of blisters during the adhesive hardening phase. In such cases it may be best to install the mats during the cooler hours of the evening and to lay the tiles the following morning. Protective measures may be necessary, e.g. against rain. Any water which may have accumulated (due to rain) in the dimple depressions must be removed before application of the thin-bed mortar. For movement joints as field limitation, edge and connection joints, the generally recognised rules of good engineering practice must always be observed. The CI++ matting must also have a suitable expansion joint. For balcony and terrace flooring surfaces, field limitation joints must be provided at intervals of 2.50 m to max. 5.00 m. With roof terraces, the corresponding applicable rules of the roofing trade must be observed. The necessary construction must be planned and executed accordingly with a vapour barrier, thermal insulation, waterproofing and surfacing.

Click the links below to see the technical specifications and user guides for this product.

Delivery Times

Delivery times for all delivery services are Monday to Friday (excluding Bank Holidays) 8am - 6pm. A 'working day' is Monday to Friday, excluding bank holidays. Weekends and bank holidays do not count as working days.

Delivery Costs

For information on delivery costs, please visit the main Delivery page.

Delivery Damages

It's important that you indicate the damages on the delivery note when you sign for the goods. Notify The London Tile Company by calling our advice line on 0333 320 80 48 if there are any damages or irregularities to your order within 24 hours of delivery.