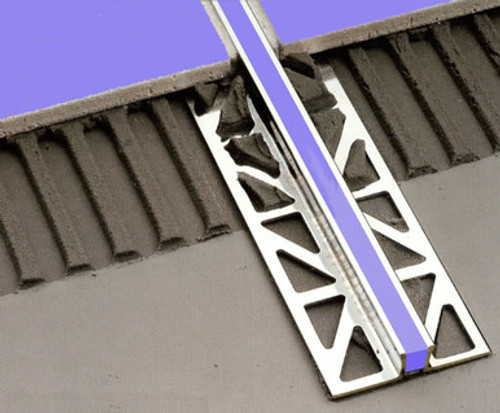

Dural Stainless Steel Movements Joints are movement joint profiles that allow and absorb lateral movement in flooring surfaces. The inserts are made from high compressive EPDM material which can be matched to any popular grout or RAL colour! This allows you to match grout or fixing colours and keep a streamlined look and feel to your project. Just add which grout or RAL colour you want the movement profile to match, and we'll do the rest!

Select your tile depth from the dropdown above. Our stainless steel movement joints are 2mm thick, with 6mm across of EDPM infill resin. This equates to 2mm - 6mm - 2mm - so 10mm horizontally per movement joint.

Please note: these items are bespoke and therefore non-returnable. Please ensure your sizing and colour matching information is correct before placing your order. Bespoke items take 5-7 working days to ship direct from the manufacturer.

They are suitable for thin-bed installations, and their EPDM compressive inserts allow for lateral movement in your floor - removing stresses that can often lead to cracking and failing substrates. These expansions joints are grey and come in 6 different thickness, from 8mm up to 20mm.

These Dural Stainless Steel Movement Joints are made from a combination of a highly durable stainless steel expansion carrier profile and full compressive EPDM inlay, and are perfect for flooring surfaces which are subject to extremely high mechanical stresses, like warehouses and production facilities.

Installers Guide to Movement Joints

This guide is intended to be a quick reference point for the selection and placement of movement joints in ceramic and natural stone surfaced floors. It incorporates the essential requirements of the British Standards and the latest guidelines from the TTA regarding the protection of heated installations. It is assumed that the installer understands the basic requirements of installation such as solid bedding of the profiles in the adhesive bed.

PVC based profiles

- Suitable for lightweight traffic only

- Provide protection from compressive and extensive movement

- They are the least expensive option

- Not ideal for protecting vulnerable tile edges from chipping

- Can ineffective and aesthetically unacceptable if used in the wrong installations.

Metal based profiles

- Aluminium based profiles are the most commonly used because they provide excellent movement protection and good edge protection. They are suitable for heavy foot traffic and soft-wheeled transport — ideal for car showrooms.

- Stainless steel-based profiles share the same benefit of movement accommodation as aluminium but have greatly increased strength allowing for greater load bearing and other stress. They are ideal for use in workshops, factories, and warehouses where hard wheeled traffic such as forklift trucks are used.

- Stainless steel is noncorrosive which makes them ideal for areas where hazardous chemicals are present such as car work shop areas, and also food and drink production areas where vigorous cleaning takes place.

- Brass based profiles are rarely used but can be required for aesthetic reasons.

Our advice is that unless cost is an overriding issue we do not recommend the use of PVC profiles. They are a short-term solution and lack the durability that is needed for tiled flooring. Using aluminium based profiles adequately protects the majority of projects. Stainless Steel profiles provide the greatest strength but are the least visible due to the manufacture and design of the profile.

When and Where to Place Movement Joints

In order to determine where to place the profiles it is necessary to inspect the subfloor because day joints in the screed or pre-existing compound joints will often be the deciding factor. Many of these existing joints are approximately 6 meters apart (British Standard guideline is a max of 10 meters) which can often cause problems with tile layouts leaving some awkward cuts. Please contact us to discuss this in more detail. Some subfloors are monolithic and have no subdivision. In these situations, the movement joint position can be adjusted to best suit the aesthetic layout of the tiling following the 10 meter guide (see section on heated floors).

- If there is a joint in the subfloor it must be followed through exactly in the tiled surface. Ignore this at your peril!

- The maximum area of tiling must not exceed 10 meters x 10 meters (see section on heated floors).

- If the floor section exceeds more than 2 meters x 2 meters a perimeter point must be installed.

- Tiling in Corridors must be protected by being subdivided with a minimum of 10 meters between the joints.

- Perimeter joints must protect obstructions within the floor area such as pillars, or fixed features.

Our advice - as a starting point use the pre existing joints in the subfloor for your layout but don’t forget the perimeter requirements. A joint in the subfloor or a change in materials (such as concrete or screed to timber) is a situation that requires a movement joint at that point. A kitchen extension or the addition of a sunroom are typical situations where vertical movement occurs.

Heated Floors

Over the last decade there has been a growth in the use of both electrical and wet system under floor heating and a parallel growth in the use of large format tiles has created a new set of problems for the installer. The first thing to remember is that the rapid expansion and contraction of the subfloor creates a very high level of stress, much higher than an unheated floor. Guidance from the British Standards has not kept up with the needs of the installer. The Tile Association have been more forthcoming in recognising that more guidance is needed. Essentially, guidelines are the same as a standard installation but with reduced field Sizes. The TTA suggests that no field of tiling should exceed 40 square meters with no one side exceeding 8 meters in length before a stress-relieving joint is installed.

Our advice — due to the high degree of stress within these installations, we suggest that there should be a distance of no more than 5 meters between stress relieving joints. It is a big mistake to ignore these sensible rules because subsequent problems are very difficult to correct.

Large Format Tiles

There is a trend for larger format tiles which are often fixed in a brick bonded pattern. This can make the installation of movement joints problematic because the joints across the bonded pattern can be very obtrusive. The installer should explain to the client the absolute need for movement joint protection. If this advice is ignored and the client insists on no movement joint protection, the installer should ask for an indemnity against any related problems. It should be noted that this is not always a defence against a claim.

Our advice — It is a wise precaution to advise your client to purchase an extra quantity of tiles to cover any replacement work. Where no existing movement joints occur in the substrate it is possible to use a flexible compound instead of grout. This follows the brick pattern. We can provide a suitable colour matched material to match all grout colours.

Finally...

All hard flooring moves independently by expanding and contracting at different rates so it is a requirement for flooring installations to have Movement Joint protection. Movement Joints are an effective way to protect ceramic and other hard floor coverings from the stresses that cause cracking, tending, or popping on the surface.

Clients generally do not like movement joints because it is felt that they can be obtrusive and spoil the aesthetic appearance of their carefully chosen floor. Specifiers and installers know that Movement Joints need to be used to absorb the natural movements in the floor. Architects are required to specify products that are fit for purpose and conform to building regulations, whilst installers have a duty to provide good advice and workmanship. Whatever your job title, our team of friendly and experienced staff are on hand to help guide you through the requirements of your projects.

We can supply standard or bespoke products and can colour match a Movement Joint infill to the grout or floor finish, dramatically reducing the visual impact of the profile within the floor.

Delivery Options

These items are delivered direct from the manufacturer and have an automatic £15.99 standard delivery charge. They are then despatched by the manufacturer on a 5-7 day service.

Please note Click & Collect is not available on these items as they are supplied direct from manufacturer.